GSK’s Nashik Facility Achieves Global BSI AMR Kitemark™ Certification

Mumbai: GSK’s manufacturing facility in Nashik, Maharashtra, has become one of the first in India to achieve certification to the international standard for antibiotic manufacturing, underscoring the company’s commitment to tackling antimicrobial resistance (AMR) through responsible production and waste management.

The World Health Organization recognises AMR as one of the top ten threats to global public health. Antimicrobials are a cornerstone of modern medicine. They prevent and treat common infections, and they can enable more complex medical procedures, like surgery, childbirth and cancer treatment, by reducing the risks associated with inadequately treated infections. Rising resistance to antimicrobials threatens to undermine modern medicine as we know it.

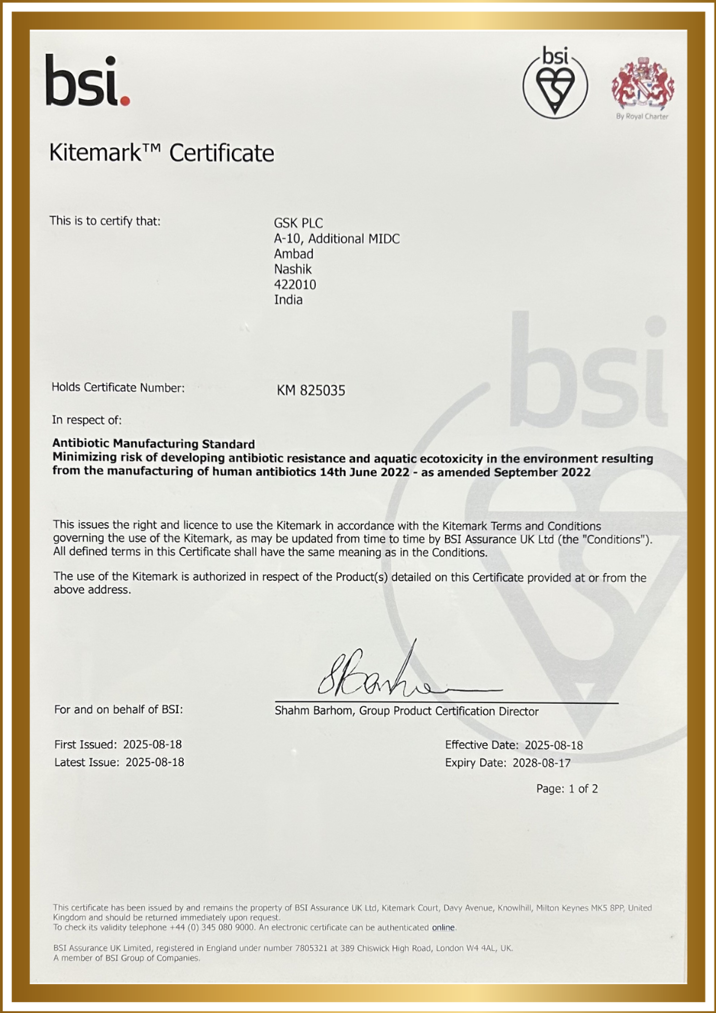

The certification, awarded by BSI, the business improvement and standards company, recognises that GSK’s Nashik facility, which manufactures, packages, and distributes antibiotics, meets the requirements of the BSI Kitemark™ for Minimized Risk of AMR. Compliance will be verified annually through rigorous surveillance audits.

This certification is also part of GSK’s broader strategy to have all internal antibiotic manufacturing sites certified by the end of 2026, reinforcing our global AMR position.

Bhushan Akshikar, Managing Director, GSK India, said: "GSK is committed to addressing the urgent public health threat of antimicrobial resistance by developing new vaccines and medicines, improving access to antibiotics, and ensuring they are manufactured responsibly. This certification reflects our actions to support India’s efforts to contain AMR and protect public health."

Courtney Soulsby, BSI Global Director, Healthcare Sustainability, said: “GSK has taken a critical step forward to address the growing threat from AMR and reduce antibiotic discharge from the manufacturing process into the environment. GSK is leading the way globally, and now in India, in the fight against antimicrobial resistance, including efforts towards responsible antibiotic manufacturing, and we hope that other organizations follow, so that we can collaborate and accelerate progress towards a more sustainable world.”

AMR occurs when microbes such as bacteria, viruses, fungi, and parasites no longer respond to treatments. Without urgent action, even minor infections and injuries could once again become life-threatening.

For over a 100 years, GSK has been a trusted partner in India’s healthcare journey. Guided by our purpose to get ahead of disease together, we remain committed to getting ahead of AMR in India by ensuring our manufacturing processes safeguard both patients and the planet.

About GSK India

GlaxoSmithKline Pharmaceuticals Limited is a subsidiary of GSK Plc, a science-led global healthcare company with a purpose to unite science, technology and talent to get ahead of disease together. For more information, visit www.GSK-India.com

About BSI

BSI is a business improvement and standards company that partners with more than 77,500 clients globally across multiple industry sectors. BSI provides organizations with the confidence to grow by working with them to tackle society’s critical issues – from climate change to building trust in AI and everything in between - to accelerate progress towards a fair society and a sustainable world.

For over a century BSI has been recognized for having a positive impact on organizations and society, building trust and enhancing lives. Today BSI engages with a 15,000 strong global community of experts, industry and consumer groups, organizations and governments to deliver on its purpose by helping its clients fulfil theirs.

BSI is appointed by the UK Government as the National Standards Body and represents UK interests at the International Organization for Standardization (ISO), the International Electrotechnical Commission (IEC) and the European Standards Organizations (CEN, CENELEC and ETSI).

The Antibiotic Manufacturing standard was developed by BSI and the AMR Industry Alliance in 2022 to outline best practice controls and methods for the responsible manufacturing of antibiotics in the global supply chain. The BSI AMR Kitemark certification provides independent assurance of the steps being taken to comply to the standard, ensuring that antibiotic waste streams containing active pharmaceutical ingredient (API) and drug products are appropriately controlled during manufacturing.

To learn more, please visit www.bsigroup.com